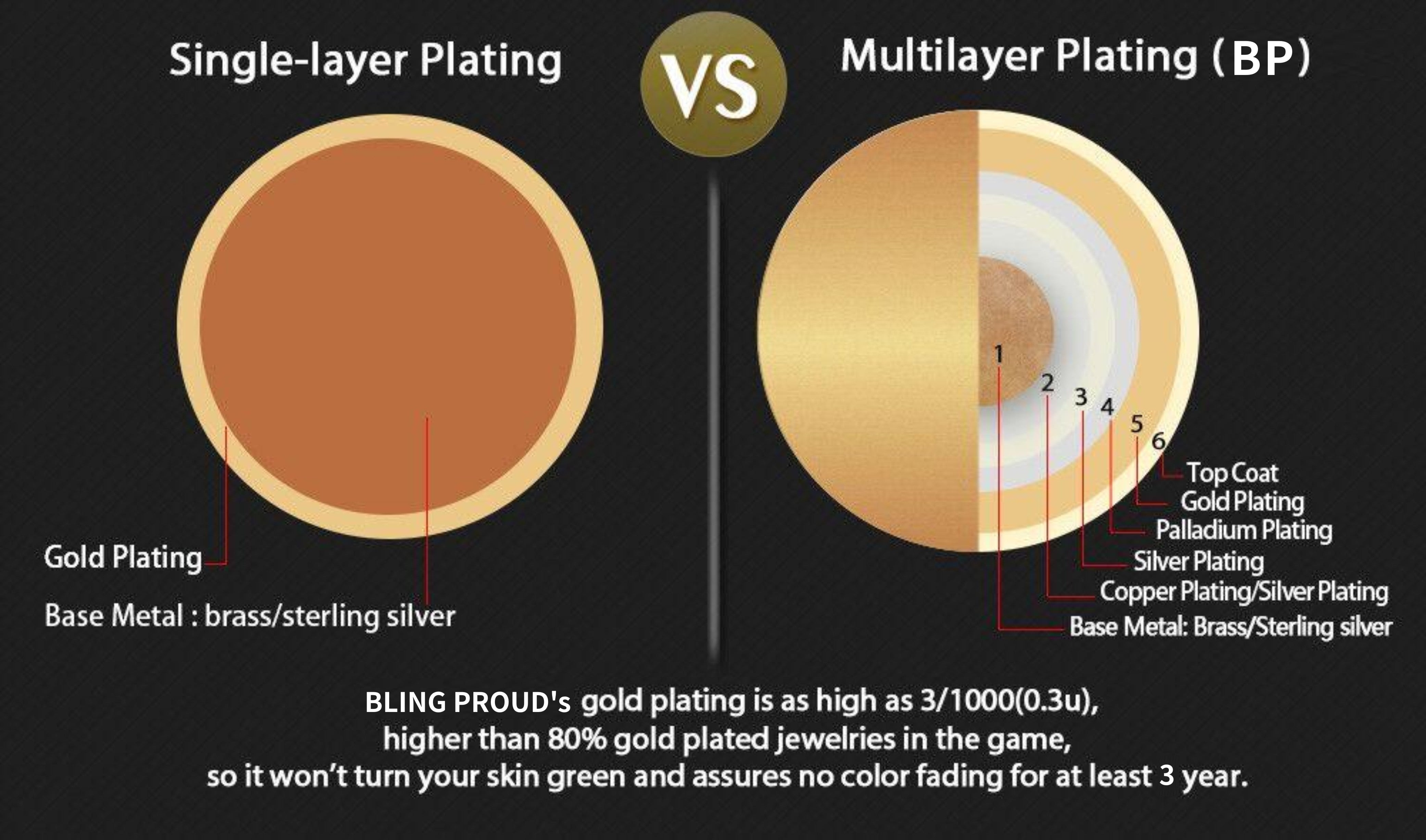

What Are BLING PROUD's 5 Times/PVD Gold Plating Technology?

The 3th plating process - The rhodium plating is a process which gives the white gold its ultra white colour by placing a coating over the existing products.

Remark: The important layers are only Palladium and Rhodium, which will keep color last longer and also expensive: Palladium (95-126USD/g) and rhodium (1200-1270USD/g).

The last step to ensure the color keep much more longer - Top coating/Nano finished.

If you choose the gold plated products - Then we do 14K/18K gold plating of our products.

Gold plated items thickness in 0.2μ Palladium + 0.1 μ Au

The second layer is Copper and silver mix ( Acid copper) plating material - Purpose Brighten the surface.

The most important part is doing one more step to differentiate out competitors - done by palladium plating. Palladium is a precious metal with numerous properties that make it an excellent choice of plating material,reliably provides a high-quality coating for our jewelry.

Remark: The important layers are only Palladium and Rhodium, which will keep color and also expensive: Palladium (95-126USD/g) and rhodium (1200-1270USD/g). In this area we thicken thickness of palladium because rhodium cost rised a lot.

If you choose the white gold plated products - White gold plated items thickness in 0.2μ Palladium+0.05 Rh ,0.1μ Rh for customized designs.

Gold plated items thickness in 0.2μ Palladium + 0.1 μ Au

All the thickness plating criteria based on the precious metal composition

3μ = Luxury brand standard.

0.003μ = Current market products standard.

PVD is a vacuum coating process that produces a brilliant decorative and functional finish

PVD coatings are more resistant to corrosion from sweat and regular wear than gold plating.

Our products are in thick plating standard.

Normal plating standard(Market standard):

0.5 TiN+0.04-0.05 mic Au(IP Gold)

0.5 TiCN+0.04-0.05 mic AuCu(IP Rose)

1 mic TiN+0.1 mic Au(IP Gold)

1 mic TiCN+0.1 mic AuCu(IP Rose)